Project Profile #3

300 kg/h and 2000 kg/h (2 MWe) pyrolysis plant for char and CHP production, B.E.S.T. Australia (2005-2007).

To download this project profile in PDF format click here.

Biodiesel scrubber and 300 kWe gas engine, Gosford, Australia (2006)

Project Background

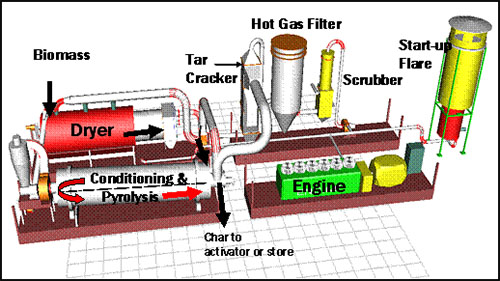

C.A.R.E. Ltd. has been working with Biomass Energy Services and Technology Pty Ltd. (B.E.S.T.) on the development of a fixed bed paddle pyrolyser for the conversion of papermill sludges, wood wastes, chicken litter and MSW derived wastes to a char product and a pyrolysis gas suitable for heat, power and combined heat and power generation.

Project summary

C.A.R.E. Ltd. has been working with B.E.S.T. in:

C.A.R.E. Ltd. has also developed design models for scale-up of the technology to 4 t/h of dried input biomass to the pyrolyser. C.A.R.E. Ltd. has helped to design the pyrolysis kiln by improving existing design models; provided advice on hot gas filtration, tar cracking and also advised on engine selection, performance and operational conditions. The plant at Gosford processes wastes for the production of a combustible gas which is used for power generation and the heat used for the drying of wood sawdust and wastes with use onsite. Byproduct char, commonly referred to as ''biochar'' is used for soil applications and R&D testing.

Status

The technology is being offered by B.E.S.T. commercially at 2 t/h and 4 t/h in the USA by BEST Energies and in Australasia and the Pacific Rim by Pacific Pyrolysis Pty.

2000 kg/h - 2.2 MWe biomass pyrolysis plant with CHP